Custom Luxury Packaging Boxes for Cosmetic Brands – Perfect for Lipsticks and Creams

Quick Quote

Specifications

| Product Info | Box Shape | Printing | Material | Treatment |

| Round box | CMYK | Artpaper + GreyBoard | Matte Lamination | |

| Custom | MOQ | Incoterms | Payment Terms | Delivery Reference (By Sea) |

| 500 Pieces | EXW | 30% deposit and balance against shipping document | North America: 3-4 weeks Europe: 3-4 weeks South America: 4-5 weeks Asia: 1-2 weeks |

Description

Product Features

Biodegradability: Paper materials typically decompose in the natural environment, reducing pollution.

Renewable Resources: Paper packaging is often made from wood or recycled paper, which are renewable materials, minimizing resource consumption.

Lightweight: Paper packaging is relatively lightweight, making it easy to transport and carry.

Excellent Printability: Paper materials are easy to print on, allowing for vibrant designs and colors that enhance brand visibility.

Protective Qualities: It effectively protects the product inside from moisture, dust, and other external factors.

User-Friendly: Paper packaging has a pleasant feel, is easy to open, and generally does not cause inconvenience to users.

Versatile Design: It can be customized into various shapes and sizes to meet diverse market needs.

View More

View More

How it works

FAQ

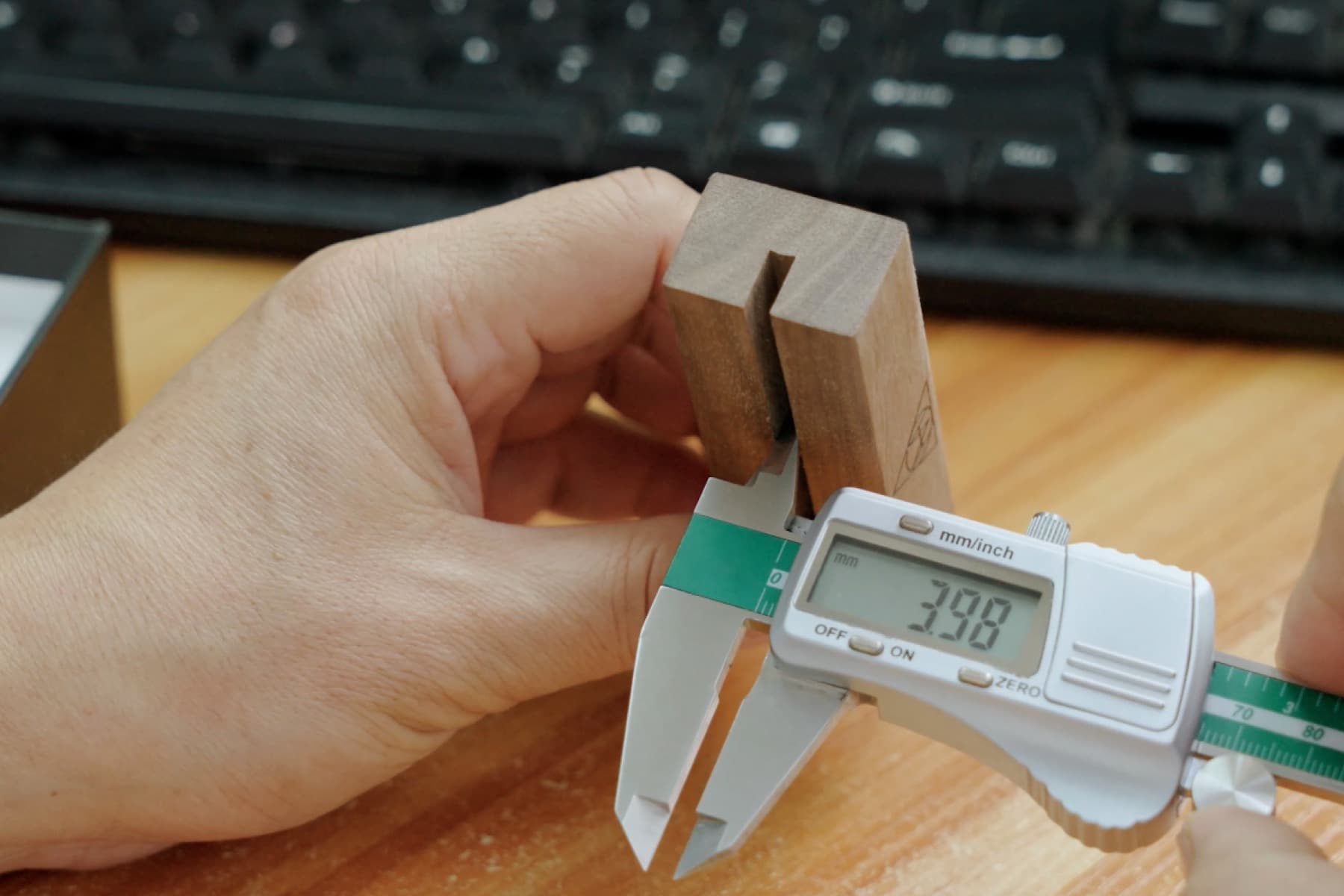

I want to customize the packaging for the product, but I don't know the appropriate packaging size, could you give me some recommendations?

What is your MOQ?

I dont need the custom product, just send me the existing product.

Can customize my own brand?

How long does it take to make sample?

More Products